Advantages of Ready-mix Concrete For Your Construction Project

Contents |

[edit] What Is Ready-Mix Concrete?

Ready mix concrete is made at a factory or a batch plant and transported to a construction site in cylindrical trucks. Each batch of ready-mixed concrete is customised to specifications and delivered ready to use. It is usually preferred for large projects and requires high volume, especially when less storage space is available for mixing the construction material.

Ready mix concrete (RMC) is extensively used in construction work due to many reasons one of which is ease of use and waste reduction, which reduces by nearly 10 to 12% with the proper mixing method of ready-mix concrete.

The quality of concrete will directly impact the strength of a structure, RMC characteristic can include compressive strength, proportioning of ingredients, workability, water-cement ratio, and slump, configured according to your project. An added advantage is the reduced air and noise pollution since RMC is produced at the manufacturing units.

[edit] Types of Ready-mix Concrete

There are three principal categories of ready mix concrete

- Transit Mixed Concrete - It is the most common concrete mix used for construction work. The ingredients are mixed in the mixer to produce the desired concrete. The ingredients are batched at the manufacturing plant and transported to your job site.

- Shrink Mixed Concrete - It is entirely prepared at the manufacturing plant. After the concrete is ready, it is shifted through concrete pumps for transportation. The mixing of the concrete happens during the transit time.

- Central Mixed Concrete - This type of concrete undergoes a significant test to ensure the appropriate quality. RMS Concrete only allows it to be transported to the construction site if the experts test it.

Why use RMC Construction Work?

Sustainable development in the construction industry is aimed at improving the quality of life for everyone, now and the next generations. The challenge for the global construction industry is to meet the growing demand for infrastructure development while minimising the impact of its CO2 emissions.

Instead of buying sand and aggregates directly, purchasing RMC can reduce site pollution and can incorporate industrial by-products such as fly ash and slag for higher durability. RMC is consistent and hardened concrete that provides a high degree of overall strength and enhances the structure's performance after maturity. Since our RMC operations are highly mechanised and electronically controlled, the chances of errors during the various operations are reduced.

The carbon intensity of the RMC will however most likely be effected by the cement products used and the manufacturing process behind the productio of clinker, which in turn will be impacted by the amount of clinker or ordinary portland cement (OPC) used in the mix.

[edit] Benefits of Ready-mix Concrete

- Greater Quality

Earlier, construction workers manually prepared concrete at the construction site, resulting in the inconsistency of concrete. On the contrary, manufacturing machines have started producing customised and superior quality ready mix concrete with each batch. Ready mix concrete provides consistency and guaranteed quality. It is sturdier and more long-lasting.

In RMC, good quality raw materials are used to manufacture concrete as it decides the outcome of the final product. RMS Concrete has a quality management system that defines inspection and testing procedures for each raw material. Using advanced software and analysis of concrete test results, our team takes corrective actions to contain the variability in the quality of concrete.

- Lower maintenance

The resilience, strength and durability of ready mix concrete mean that buildings constructed from it will remain in better condition for years. It will also reduce the maintenance cost in future. You may need minor maintenance, but overall, it is more durable than site-mixed concrete.

- Saves Time

Regardless of the order size, deliveries of ready mix concrete are timely and efficient. Time is the most critical aspect of construction work, and choosing a ready mix concrete will avoid delays caused by dismantling on-site mixing equipment. It will help you get straight to performing your job.

- Versatility

Ready mix concrete suits a wide range of applications. It is mixed to the exact specifications of the customers. It means the batch is created to use in some regions of a project - for instance, the concrete is uniquely crafted to suit the foundation of a pond or mixed with the requirements of the building foundation.RMC is more flexible and provides better results. Although it is a computerised procedure, it allows you to make last moment changes according to the needs of your project.

[edit] Conclusion

Any construction work needs durable ready mix concrete to build it efficiently. Ready Mix Concrete's unparalleled durability helps you build quality and time-saving structures.

[edit] Related articles on Designing Buildings

- Admixture, additive or agent.

- Admixtures in concrete.

- Alkali-activated binder.

- Alkali-aggregate reaction (AAR).

- Alkali-silica reaction (ASR).

- Architectural concrete.

- Blocked concrete delivery pumps.

- Cast-in-place concrete.

- Cellular concrete.

- Cement and concrete companies release 2050 Climate Ambition.

- Cement-free precast product.

- Cement mortar.

- Concrete batching plants.

- Concrete boom pumps.

- Concrete in aggressive ground (SD 1).

- Concrete joints.

- Concrete masonry unit CMU.

- Concrete repair mortars.

- Concrete-steel composite structures.

- Concrete superplasticizer.

- Concrete to cover.

- Concrete vs. steel.

- Concreting plant.

- Decarbonising concrete in the UK.

- Defective Concrete Blocks Grant Scheme.

- Differences between jumpform and slipform climbing formwork systems.

- Glass reinforced concrete.

- Hempcrete.

- How to clean concrete.

- Laitance.

- Lime concrete.

- Limestone calcined clay cement LC3.

- Portland cement.

- Precast concrete.

- Prestressed concrete.

- Power float.

- Pyrite and mica redress issues in Dail Eireann.

- Rebar.

- Recycled concrete aggregate RCA.

- Reinforced concrete.

- Scabbling.

- Screed.

- Self-compacting concrete.

- Slip form.

- Smart concrete.

- Spanish brutalism.

- Stationary pump skills.

- Stratification of concrete.

- Testing concrete.

- Textile-reinforced mortars TRM.

- The properties of concrete.

- The World Recast: 70 buildings from 70 years of Concrete Quarterly.

- The use of concrete structures to protect construction sites.

- Thomas Edison's concrete cottages.

- Types of concrete.

- Ultra high performance fibre concrete.

- Vibration Compaction Technology.

- What will happen if we use too much rebar in concrete?

Featured articles and news

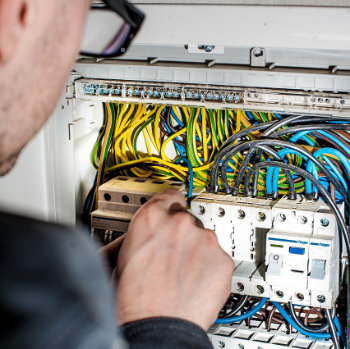

Focussing on the practical implementation of electrification.

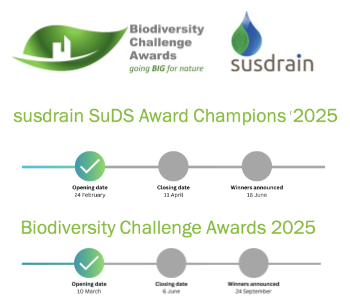

Sustainable Urban Drainage and Biodiversity

Awards for champions of these interconnected fields now open.

Microcosm of biodiversity in balconies and containers

Minor design adaptations for considerable biodiversity benefit.

CIOB student competitive construction challenge Ireland

Inspiring a new wave of Irish construction professionals.

Challenges of the net zero transition in Scotland

Skills shortage and ageing workforce hampering Scottish transition to net zero.

Private rental sector, living standards and fuel poverty

Report from the NRH in partnership with Impact on Urban Health.

.Cold chain condensing units market update

Tracking the evolution of commercial refrigeration unit markets.

Attending a conservation training course, personal account

The benefits of further learning for professsionals.

Restoring Alexander Pope's grotto

The only surviving part of his villa in Twickenham.

International Women's Day 8 March, 2025

Accelerating Action for For ALL Women and Girls: Rights. Equality. Empowerment.

Lack of construction careers advice threatens housing targets

CIOB warning on Government plans to accelerate housebuilding and development.

Shelter from the storm in Ukraine

Ukraine’s architects paving the path to recovery.

BSRIA market intelligence division key appointment

Lisa Wiltshire to lead rapidly growing Market Intelligence division.

A blueprint for construction’s sustainability efforts

Practical steps to achieve the United Nations Sustainable Development Goals.

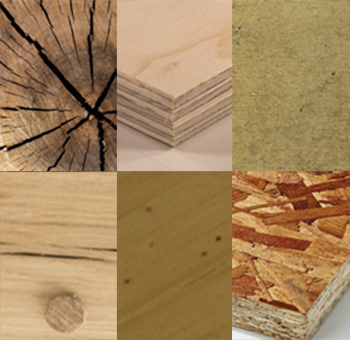

Timber in Construction Roadmap

Ambitious plans from the Government to increase the use of timber in construction.

ECA digital series unveils road to net-zero.

Retrofit and Decarbonisation framework N9 launched

Aligned with LHCPG social value strategy and the Gold Standard.